Infrastructure, Road- & Waterworks

Civil road and hydraulic structures such as movable locks, bridges and flood defences form an important part of the Dutch infrastructure. They protect us against the rising water. Over the past decades, Hydroton has annually carried out various projects in the field of civil road and hydraulic engineering in the Netherlands and Belgium. These projects are managed by a project team. The members of the project team will be your regular point of contact, from the design phase to the delivery. They will take care of the designs, supervise the production process, monitor quality and acceptance tests. Ultimately, they will hand over the drive to the customer on location. This pragmatic approach results in short communication lines, efficiency, ownership and clarity. As a result, the project will be running as smoothly as possible.

Check out a few of our projects:

Controlled drilling and trenchless techniques

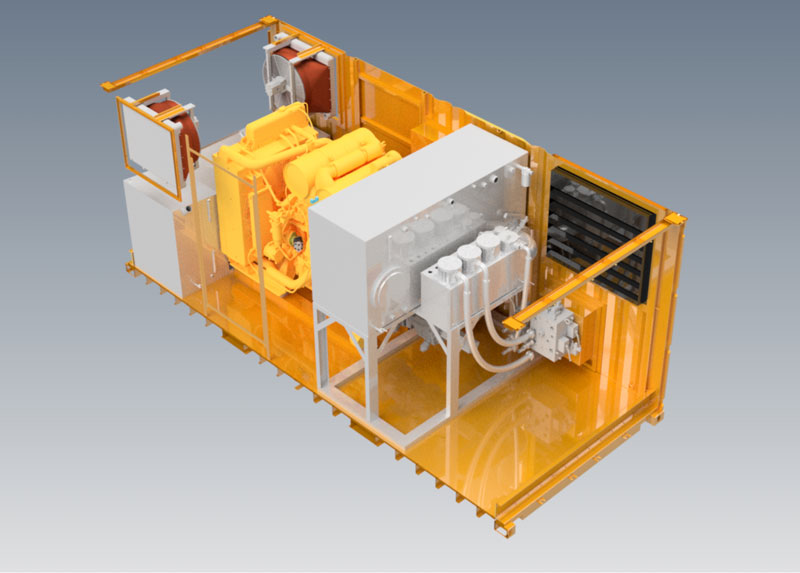

This mobile hydraulic drive (Power pack) is equipped with a 640 hp strong C18 Caterpillar (Stage V) and five hydraulic pumps that can deliver a total of 1000 liters per minute. Thanks to the power control, the maximum working pressure is 420bar. The power pack is constructed in a CSC certified 20ft sea container, which makes transporting the container overseas easier and less expensive. The installation drives a pipe pusher that has been developed and built by the customer in-house. This set is used worldwide to carry out directional drilling.

“The power pack is constructed in a CSC certified 20ft sea container, which makes transporting the container overseas easier and less expensive.”

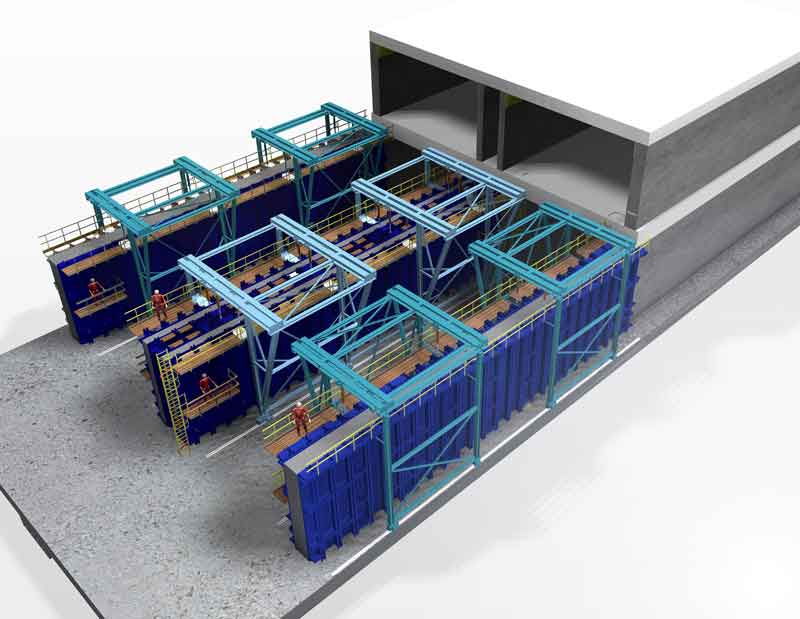

(Hydraulic) formwork for land tunnel

There are many land tunnels (tunnels on the mainland) in the Netherlands. Land tunnels are created using the open construction pit method. Hydroton is experienced in designing the hydraulic drives for the concrete formwork and moulds used for pouring the concrete walls and ceilings of such tunnels ‘on the job’. Our expertise was utilised during the construction of the double-deck land tunnel in the A2/N2 highway through Maastricht, and the ‘De Groene Boog’ project in the A16 highway near Rotterdam.

Customised solutions

We supply turnkey customised solutions, where the entire formwork mould moves, lifts, slides and stamps, powered by our hydraulic units, lock nut cylinders, double-acting cylinders and electro-hydraulic drives. The electronic control and operation is managed using remote controls developed by us. Our specialists also take care of the on-site connection and troubleshooting.

“Hydroton is experienced in designing the hydraulic drives for concrete formwork and moulds.”

Bilderdamsebrug Leimuiden

The outdated hydraulic drive of the Bilderdamsebrug in Leimuiden needed to be replaced. The design of the new drive by Hydroton represents a major step into the future for the antique drawbridge in picturesque Leimuiden. The new hydraulic power unit is equipped with an internal gear pump which ensures a low noise level. Thanks to the manually operated pump, the bridge can also be operated by hand. The reservoir, the drip tray and the piping are made of stainless steel to guarantee a long life span. Hydroton took care of the design, production and installation and commissioning on site.

“Hydroton works closely with the various parties within a hydraulic engineering project.”

Bridges, Locks and Infrastructure

The high standards set by the government (Rijkswaterstaat, ProRail, municipalities or others) are a perfect match for Hydroton’s quality level. We meet all quality and safety standards such as NBD06000, VOBB and NEN-4413 required by the client. When our dedicated specialists discover improvement opportunities in the design that are not prescribed in the requirements or specifications, they will address this. Those improvements may include improvements in safety, extended service life and reliability of the hydraulic system. By being proactive in the design phase, the realisation phase often runs more smoothly. This is where Hydroton can make a difference within your project.

“The high standards set by the government are a perfect match for Hydroton’s quality level.”

Reevelocks Kampen

The new lock complex in the Reevediep between Dronten and Kampen safeguards the water level of the surrounding lakes, thanks to the sluice gate, which is equipped with four lifting doors. In addition, ships are using the ship lock, which is fitted with two doors with integrated ratchet gates. The drive is equipped with a total of five hydraulic units and twelve double-acting cylinders and length measuring systems. The stainless steel piping was tailor-made and installed on site. The entire system was delivered to Rijkswaterstaat in mid-2021.

“The drive is equipped with a total of five hydraulic units.”

Temporary drawbridge

This bridge can be used worldwide as a temporary drawbridge, during the renovation of a local bridge for example. Thanks to the innovative accumulator system, hydraulic energy is stored when the bridge is in its resting position. As a result, the power consumed is low, but the time it takes to open and close the bridge is not affected. The hydraulic drive is set up in a 20ft container, designed for easy disconnection. The two hydraulic cylinders – equipped with a bore of 480 mm and a working stroke of 5500 mm – are equipped with length measuring systems and an electronic synchronisation control that controls the servo valves. In 2018, this temporary drawbridge was put into operation for the first time in Westknollendam, commissioned by the province of Noord-Holland.

Stationsbrug Middelburg

The Stationsbrug (Station Bridge) in Middelburg is a 70 year old monumental swing bridge. This bridge was lifted from the foundation at the end of 2019 and completely restored and modernised. Hydroton supplied the new hydraulic drive for the moving and locking of this iconic bridge. The drive is equipped with modern feedback, so the bridge meets the latest requirements. The original piping has also been replaced by stainless steel pipes and all connections have been made using the walform method. After a successful commissioning, the bridge was reopened to traffic in 2020.