Water hydraulics & Special fluids

Water hydraulics are often used in systems where oil may not be used. Hydroton is a distributor and importer of products from The Water Hydraulics Company (Great Britain). Thanks to many years of partnership with TWHC and experience with the components and systems, we can offer you expert advice on the application of this environmentally friendly alternative to conventional hydraulics. We supplied dozens of customised water hydraulic systems and cylinders for cleanrooms, swimming pool floors, reverse osmosis rigs, fire protection systems and test setups in the Netherlands and abroad. In addition to complete drives, we supply individual products from the TWHC range.

Check out a few of our projects:

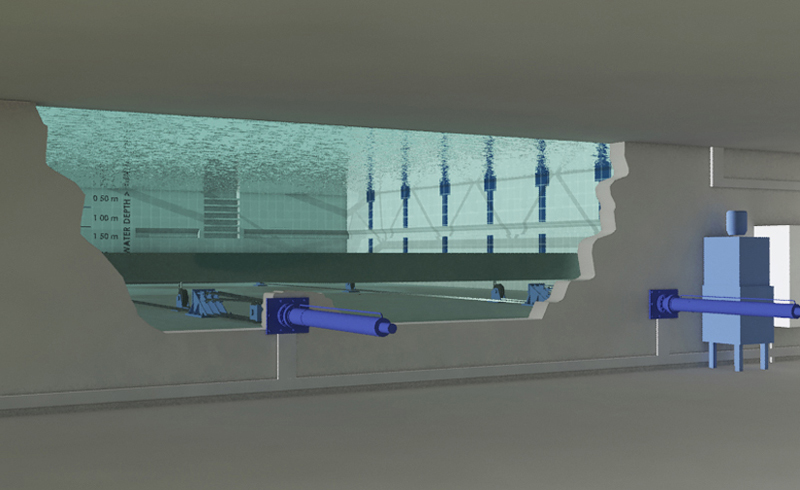

Wave dampers in test basins

For one of Hollands largest maritime research institutes, MARIN, Hydroton supplied two custom made water hydraulics driven systems on behalf of a steel constructor. Models of ships are tested within this institute and waves are generated in two test basins. To simulate open water, the waves have to disappear, as happens on a sandy beach. The steel constructor supplied a movable construction that met this requirement. The construction had to be able to be moved in order to position the dampers in a different position. For example, to simulate a channel, where the wave action is driven back to the ship by the quay.

Hydroton supplied two redundant water-hydraulic units with over 40 custom-made hydraulic cylinders, which are completely made of stainless steel 316 and special seals. All cylinders are set up under water. The on-site installation was executed by Hydroton as well. The choice for water hydraulics was made by the customer because the (sea) water in the test basins must never be contaminated by oil or liquids other than water in the event of an unexpected leak. This would negatively affect the test results.

“The construction had to be able to be moved in order to position the dampers in a different position.”

Cleanrooms

Water hydraulic systems are used to open heavy vacuum boilers within cleanrooms. Cleanrooms are mainly used in micro-technology and are designed and conditioned to create a very clean working environment. Within this environment, production processes are carried out for, for example, the vapor deposition of coatings on small parts such as chips and wafers. Because the highest cleanliness must be maintained within this space, Hydroton supplies water hydraulics, so that only water can escape in the event of an unexpected calamity. Especially when using vacuum systems, it is very important that no oil mist or oil leakage can occur, as this will damage the product and seriously pollute the cleanroom.

Hydroton supplied a total of 2 hydraulic units, 6 manifold assemblies and 38 custom-made cylinders for two manufacturing lines in the automotive industry. The installation and commissioning of all stainless steel piping in Germany was also carried out by our specialists. Due to a NDA, on-site pictures cannot be shared.

“Because the highest cleanliness must be maintained within this space, Hydroton supplies water hydraulics.”

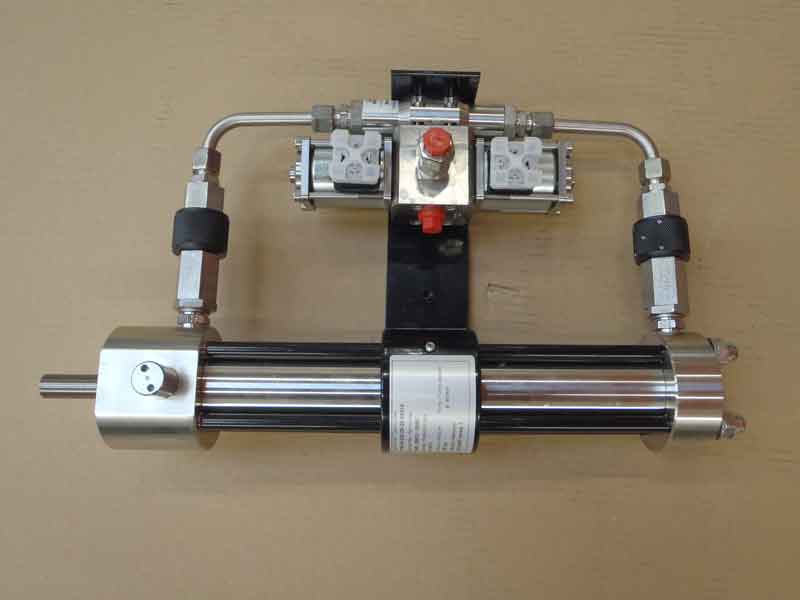

Offshore skid

This set-up is placed in a 10-foot sea container and is used as an offshore test set-up. The unit is equipped with a high pressure pump that works with hydraulic oil and a high flow pump that works with water. The water side has a flow of 240 liters per minute at an operating pressure of 85 bar. All components are custom made for this application by The Water Hydraulics Company. You can contact Hydroton for large flows and special applications in the field of water hydraulics. Our experienced team is at your service.

“You can contact Hydroton for large flows and special applications in the field of water hydraulics.”

Movable swimming pool floors

Movable swimming pool floors are powered by water hydraulic systems. Water hydraulic systems are used to ensure the pool water will never be contaminated by oil. Our engineers have the knowledge and experience needed to design and manufacture well-balanced water hydraulic units. In addition to the power pack, both double-acting and single-acting hydraulic cylinders are designed and built in-house. The high-quality stainless steel and materials used for the custom-made seals are key to developing a perfect, long lasting system.